Sorry for the radio silence folks, I’ve been putting off writing, work’s been kicking my ass a bit lately, we’ve changed up the software we use to do all of our engine testing in my lab at Ford, so there’s been a lot to figure out. It’s as if I took a new job, but I didn’t get a raise, and I’m still expected to know how to do everything already and meet deadlines.

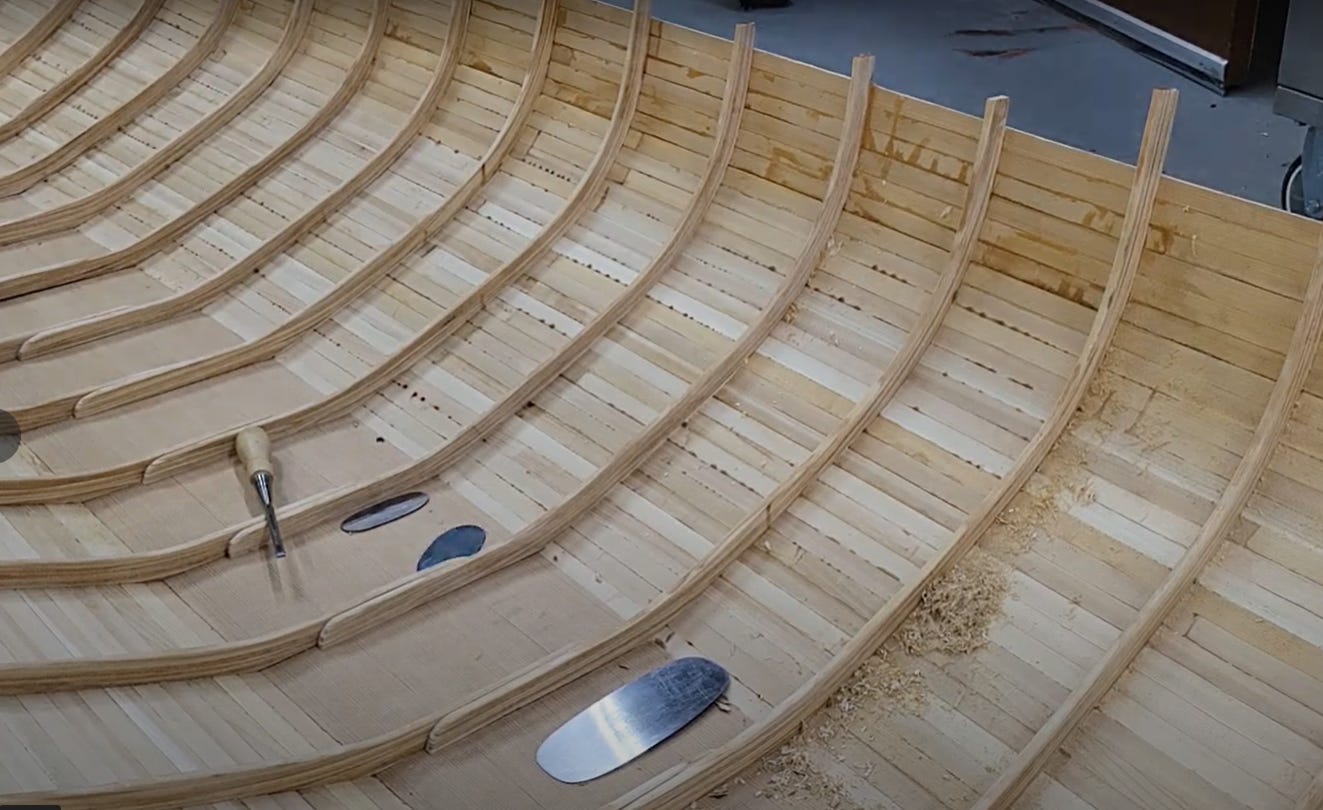

So, we left off with a faired exterior hull, now it’s time to fair the inside of the hull. No easy task, cedar strip canoe builders hate this part. It’s even more of a pain in the ass when you have 24 sets of ribs you need to work around:

So let’s start by circling back to our problem. This boat is made up of a bunch of 1” strips, which bends and curves nicely, but leaves a series of peaks and flats where you want curves:

For the most part, this boat is convex on the outside of the hull, meaning we only really need to knock down the peaks along each seam to make curves. The interior requires us to hollow out the flats, or at the very least, scrape down to the seams of each glue line to remove excess glue and clean up each joint.

To illustrate this point, I’ll post a picture of my lovely family checking on my progress. On the far side is a lot of glue squeeze out, yet to be removed. On the near side, I’ve already scraped away most of the offending material. Kelley would kill me if she knew that I posted a picture of her. Luckily for me, no one reads this blog. Relatedly, we’re also expecting another boy in June :-)

These guideboat seats are filling up fast! I guess mom’s gonna have to find another boat if she wants to fish.

But what even is a scraper? A card scraper is basically just a soft piece of steel that’s soft enough to to be burnished, creating a hooked edge that can be used like a plane blade.

By shaping a piece of spring steel to a curve, then refining the edge to a hook, you can scoop out cedar and glue until you are left with a faired surface ready to be sanded.

This also involves using a chisel to flick out glue boogers before following up with a scraper. Several scrapers were ground to different curves, different sizes, and all sharpened at the same time to run through until they all lost their edge. You really have no choice but to become (moderately) proficient at burnishing scrapers by the end of this process. Because it’s a process. And you sharpen a lot. And you scrape a lot. At the start each section took maybe 15 minutes. By the end each section took maybe 5-10 minutes. There’s something like 52 sections there. This is fun!

It was fun. I even made a youtube video about grinding scrapers to different profiles. I’ll spare you the video, but here’s a taste:

Finally the scraping was done and it was time to sand

I picked up a Metabo SXE400 which I like very much, except no one else makes a 3.25” sanding disc, so you’re on the hook to metabo to keep feeding your habits. Still, a great tool, great dust collection, once you tape your shop vac to it!

And that about does it!

Some additional book keeping, this was around Christmas so Teddy helped me pick out a tree

And inspect the lights

So that does it for this one! We will pop the boat back on the form to finish sanding and prime/painting the hull before we finish up with the interior.

Until next time, Happy Easter, and Happy Woodworking!